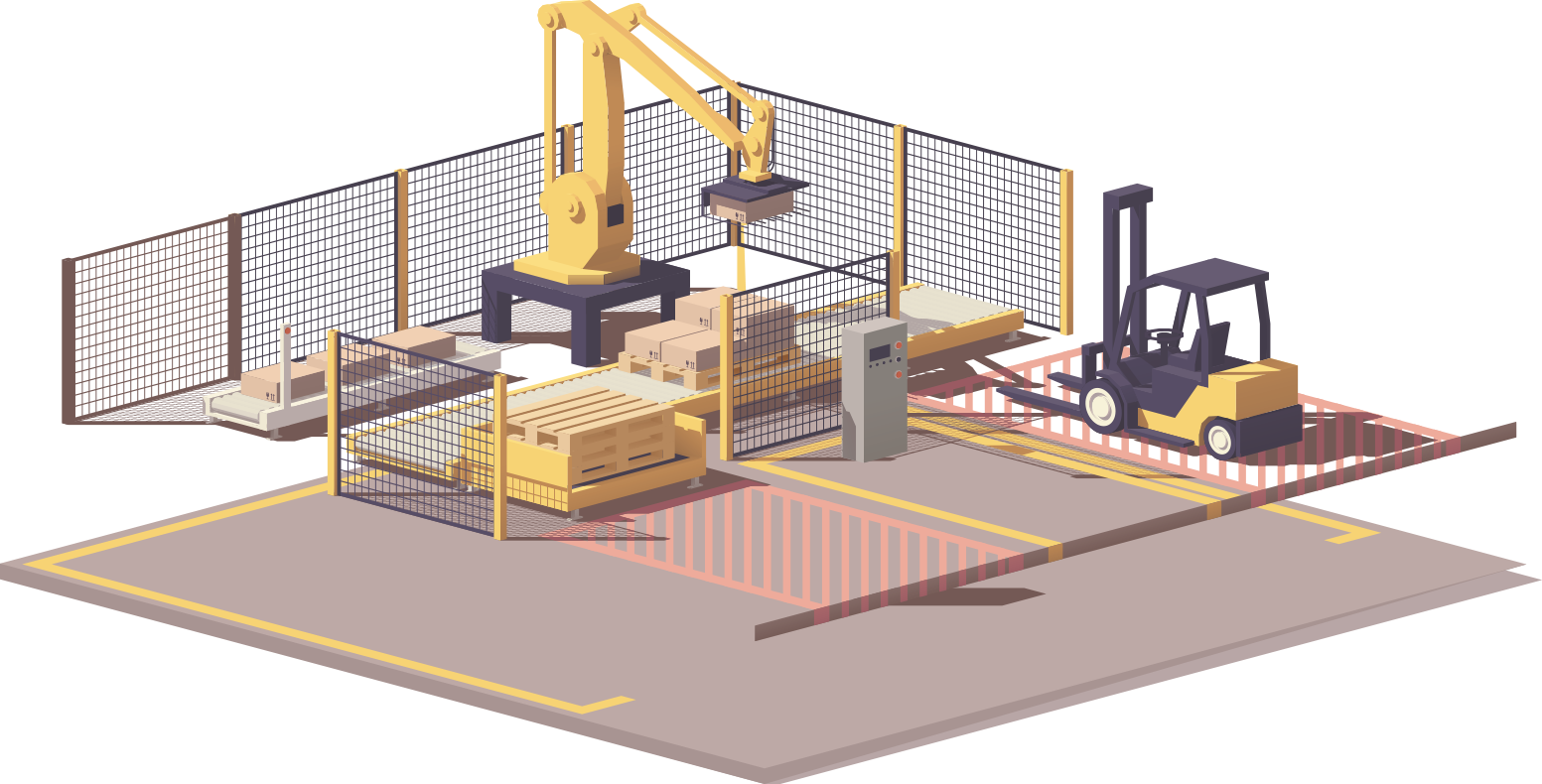

Palletizing with robotic systems provides the capability to create complete pallets with maximum speed and flexibility. Robotic arms are selected based on strict criteria to meet the requirements of movement range, maximum load, and motion accuracy.

Depending on the application, they can be combined with specialized end-of-arm tooling (e.g., suction cups, grippers, etc.) to safely and accurately handle various products (boxes, containers, bags, intermediate protective sheets).

The management of empty pallets, depending on the production line size, can be done either manually or with a fully automated pallet handling system.

Kapelis Packaging, in collaboration with Stantech, offers a variety of solutions depending on your production size. Specifically, they are categorized as follows:

• Semi-automatic palletizing machines: Suitable for small production lines. The pallet change is done manually. There is an option to implement a robotic Cobot system to minimize the required space.

• Automatic palletizing machines: Suitable for medium-sized production lines. Speed of up to 15 cartons per minute. The pallet change is robotically assisted, using the same robotic system for the operations of placing boxes on the pallet, placing the empty pallet at the loading point, and placing intermediate protective sheets if required. This configuration can be combined with an automatic pallet wrapping machine.

• Automatic palletizing machines for multiple production lines: This solution includes automatic pallet placement, wheeled trolleys for transporting both empty and completed pallets. They can be combined with various additional configurations such as automatic pallet wrapping machines, pallet labelers, and printing systems connected to enterprise resource planning (ERP) systems.

FANUC

The FANUC manufacturer is the global leader in industrial automation. Fanuc robotic systems use the most advanced methods and tools (Software/Hardware), ensuring ease of programming, rapid installation times, and maximum flexibility in reconfiguration.

COBOT

Collaborative robots or COBOTs are an ideal solution for small or medium-sized production lines with space constraints. They cover a wide range of applications and can operate almost anywhere in a factory, as their programming and installation are done very quickly, and in most cases, specialized training is not required.