The Italian manufacturer Reepack s.r.l., a member of the American Promach group, is a leading company in high-quality packaging equipment across a full range, including thermoformers, tray sealers, and horizontal flowbag loaders suitable for fresh products. Reepack specializes in manufacturing packaging machines with a wide range of semi-automatic and fully automatic machines. Their extensive experience in packaging machinery manufacturing ensures a deep understanding of the production requirements imposed on machines in this application area. Reepack serves customers across all packaging applications with innovative solutions, leveraging their extensive range of technologies, design expertise, and the combination of strategic partnerships and manufacturing strength.

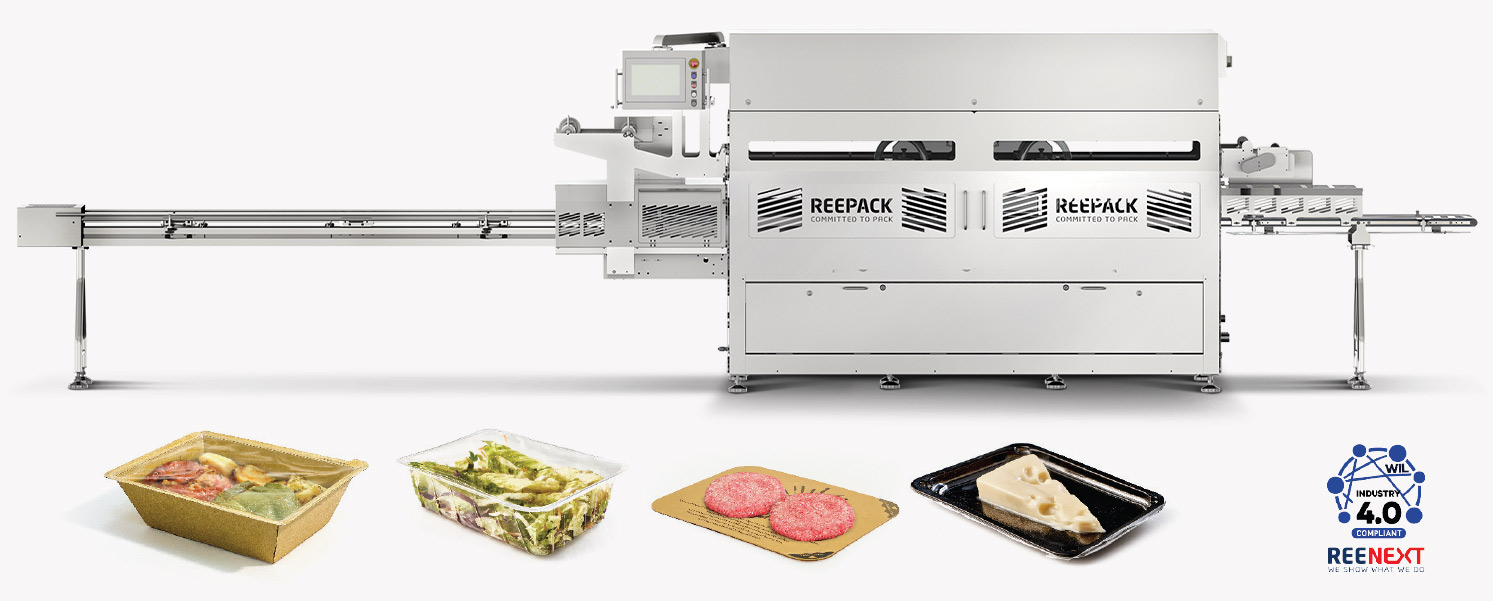

Made entirely of stainless steel, its ergonomic and highly hygienic design allows for easy and quick cleaning. The ReeMaster series machines are capable of stable and perfect sealing, modified atmosphere MAP, and Skinpack and Pro-Skin packaging. The ReeMaster automatic tray sealing machines stand out for their excellent sealing results and high productivity, thanks to their specially designed mold, reaching up to 20 operating cycles per minute. The sealing head is servo-driven, ensuring guaranteed results in 100% of production. The system can be configured with single or dual tray feeding lines, and with the advanced TPS positioning system, it is possible to pack up to 8 trays in two lines. The sealing head is fed with trays via an automatic gripper system. The movement of these grippers is precisely controlled through the control screen, and the servo motor ensures the safe transfer of product-filled trays.

They can be combined with various equipment such as filling and weighing machines on the line, label printers, lid sealers, etc. They also feature Reepack's unique Active Film Tensioning System (AFTS) for consistent and reliable sealing results in skinpack packaging.

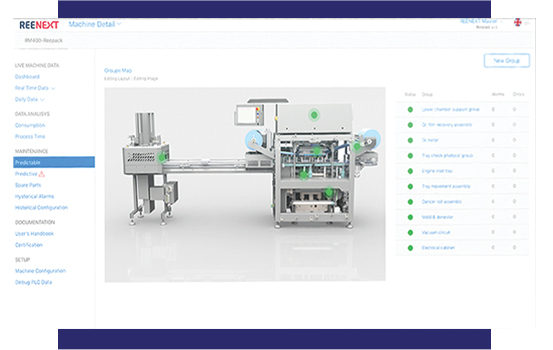

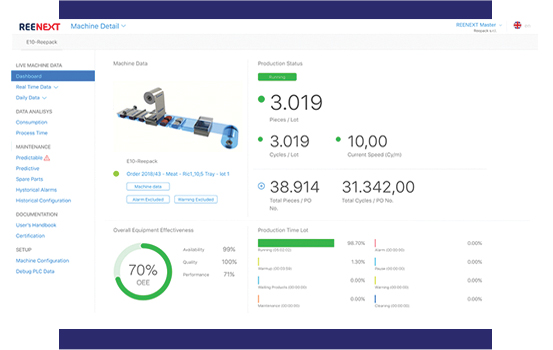

The ReeNEXT technology allows continuous machine connectivity, providing users with "smart" information. Through sensors appropriately placed inside the machine and advanced software, it is possible to monitor elements such as production flow, water, air, gas, and packaging film consumption in real time. This data helps optimize production and resource management.

Using the ReeNEXT platform, you can achieve flexible, efficient, digital, and trouble-free production. Data management is the fastest path to innovation in the industry.

ReePack's high-productivity automatic thermoforming machines, T45-T55, are characterized by great flexibility and customizability, as they can be combined with a variety of specialized configurations and equipment, offering perfect and modern packaging solutions. ReePack thermoforming machines are primarily servo-driven (Eco-line), using compressed air only for low-load and consumption processes, significantly reducing maintenance and energy costs required for the machine's main movements. They feature a robust construction made entirely of stainless steel, and combined with their ergonomic and highly hygienic design, they facilitate maintenance and complete cleaning. They are equipped with a clear touchscreen for easy parameter settings and the ability to store many different customized programs.

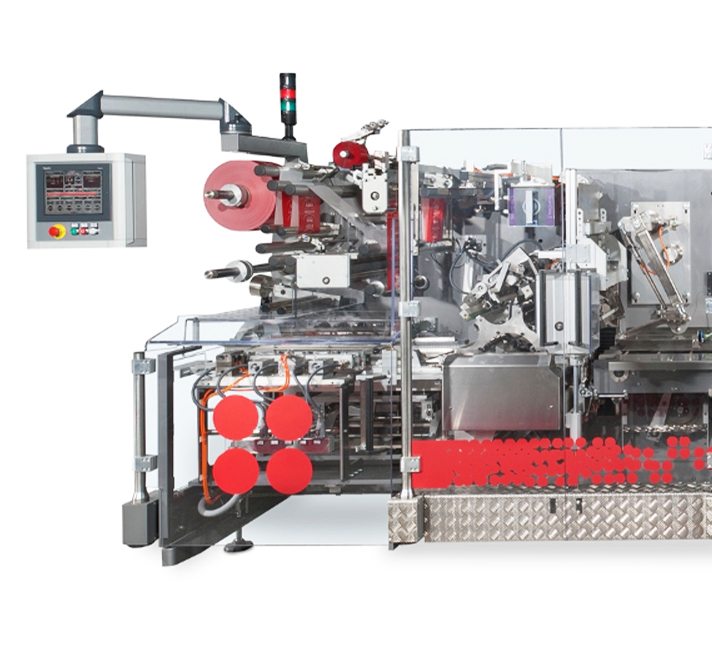

An industrial servo-driven construction suitable for operation in multiple shifts 24/7, with four longitudinal sealing rollers for high productivity, suitable for hot and cold sealing, ideal for modified atmosphere packaging or alcohol injection, and easy connection to automatic product feeders. With the appropriate feeding system and six servomotors controlling the smooth product flow, the HBTS machine series can package up to 1,100 pieces per minute, achieving excellent results. It features electronic implementation and topologies by Allen Bradley, Kevlar jaws for cold film sealing, automatic control, and rejection of non-compliant packages.