A packaging type that gains ground in retailing.

Foam tray, wrapped with stretch film, is often used. However, this packaging does not offer any special protection for the product.

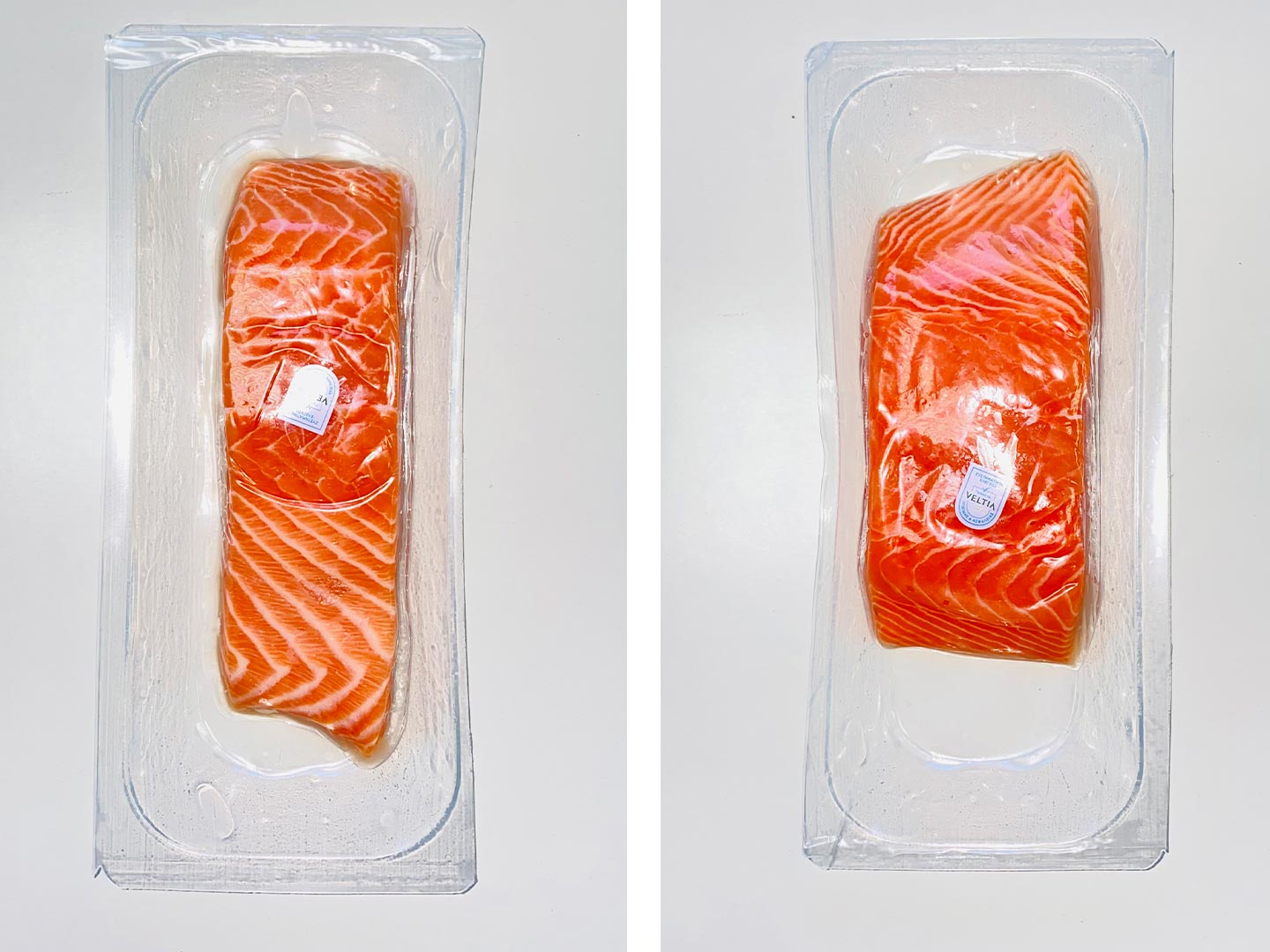

Modified atmosphere packaging (MAP) is used to prolong the life of fresh fish. Often with increased Oxygen levels to avoid the development of anaerobic microorganisms, although this is not necessary in oily fish (food technology should decide on each type of fish). Typically, PP containers, either preformed or produced by a thermoforming machine, are used. They do not have a high gas barrier, but they can prove to be effective in practice because of the limited lifetime of the fish. High-barrier PPs with EVOH are always best for long-term maintenance of the MAP gas mixture. High gas barrier trays are also CPET trays which can also be baked in the oven, and therefore are suitable for marinated fish or other ingredients, that is, a ready meal.

In order to use MAP, a high barrier film is necessary.