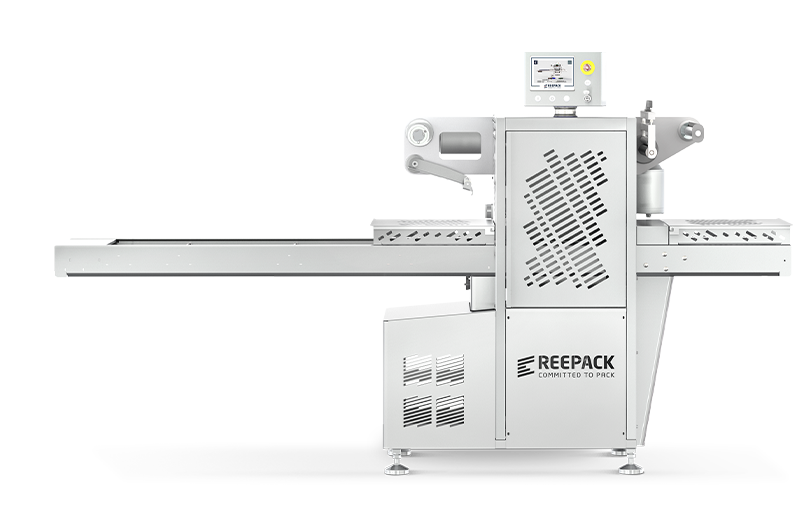

ReeEco is the smartest way to bring your mid-size tray lid production to the automated packaging world.

Ideal for packaging fresh or frozen food and ready meals, ReeEco is capable of a solid sealing, Modified atmosphere process (M.A.P.) and Vacuum Skin Packages. Compatible with a wide range of packaging materials (PP, PE, C-PET, A-PET, etc.).

Tray transport driven by pushing rods guided on both side by chain, double movement or step by step gentle and controlled until the defined die-set position.

The machine is fully electric (Eco-line) – No compressed air required! This feature reduces remarkably the energy related costs, as well as the maintenance costs.

ReeNEXT is a system which allows to monitor every packaging line parameter, permitting to read it from the machine and also to transfer data to the packaging line.

It offers a wide range of tools, including Real-time monitoring, Data analysis for consumption of energy and consumable materials.

The real-time monitoring the status of critical assets of the machine gives the ability to manage them with predictable and predictive operations.