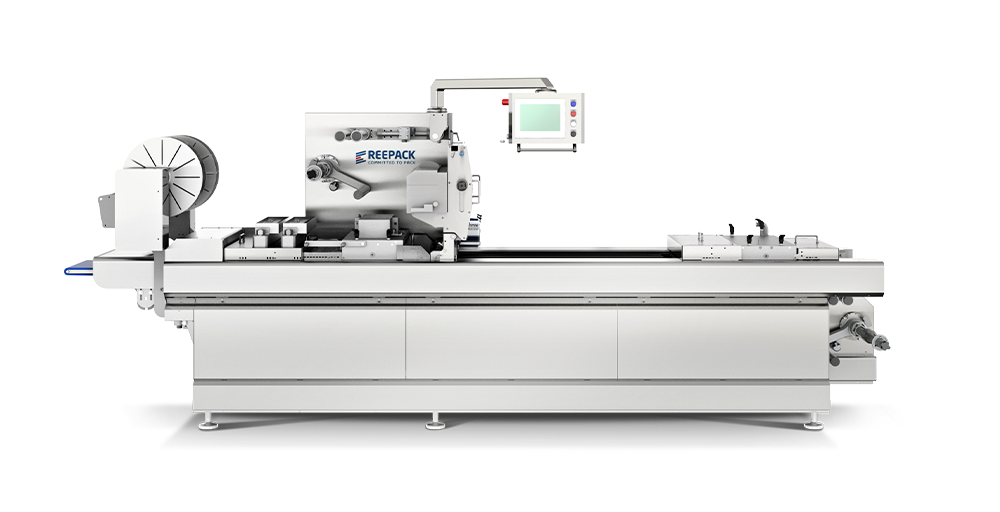

Thermoforming Machines – ReeForm Series

Kapelis Packaging S.A., in collaboration with the highly esteemed Italian manufacturer REEPACK, offers the pinnacle of technological advancement and production efficiency through the ReeForm range of thermoforming machines· the leading choice in thermoforming machines offering incomparable quality, high productivity and a wide range of capabilities and features in order to fulfill any packaging demand.

Reepack is a company operating in the field of packaging machinery manufacturing with an extensive range of manual, semi-automatic and fully automatic machines. High experience in packaging machinery manufacturing has given Reepack a deep understanding of the demanding production requirements to which machinery in this field of application is subject. Reepack serves customers across the spectrum of packaging applications with innovative solutions by leveraging its extensive array of technologies, design expertise and combination of intellectual property, strategic partnership and manufacturing strength.

The ReeForm series of thermoforming packaging machines offers a wide range of machines to meet any individual requirements. From entry-level to flexible and compact models, up to high performance machines processing flexible and rigid film, with different thickness for differing film width, forming depth and cut-off length configurations.

The ReeForm series of thermoforming packaging machines operates mostly on electrical power (Eco-line) excluding any additionally required pneumatic support. An electrically operated packaging machine constitutes the ideal system where performance, servicing and energy saving are top priorities.

Additionally, the innovative ReeNEXT platform can be used for end-to-end coordination of the packaging line. It guarantees a fast and accurate recording of the processes and it is easy to use for networking and transferring production data to your business management and data structure.

ReeNEXT enables the monitoring of every packaging line parameter, while observing and reading them from the machine and also enabling the transferring of data to the packaging line.

It offers a wide range of tools, including real-time monitoring, data analysis for consumption of energy and consumable material, predictive maintenance, as well as tracking and tracing of your products.

Many customers are using MES tools to plan, control and analyze their company’s production processes. With the ReeNEXT platform provided by Reepack, we conveniently interface our automation solutions to your ERP/MES system.