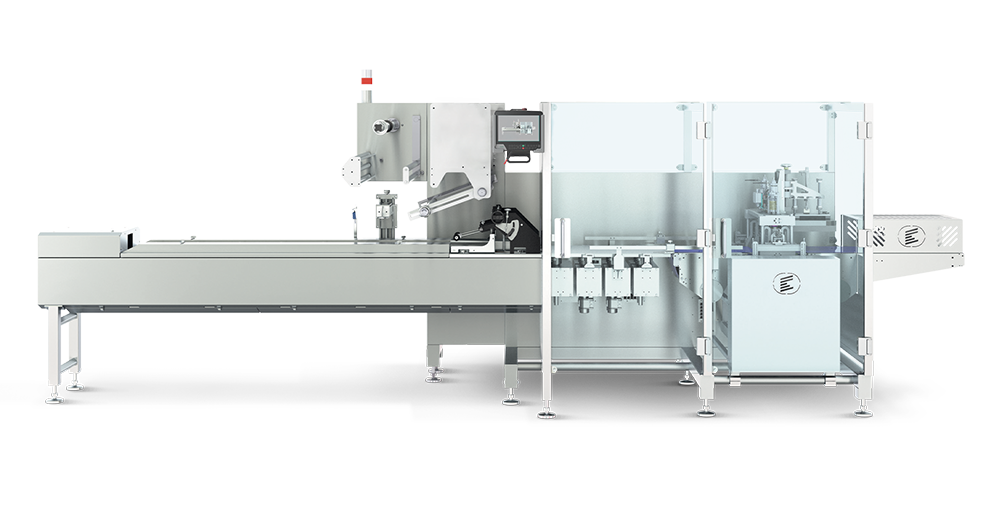

The ReeFlow 200 series of horizontal flow-wrapping machines, equipped with the new-generation Long Dwell sealing system, stands out for its high sealing speed and is the ideal solution for packaging a wide range of products in Modified Atmosphere Packaging (MAP) environments.

Their construction, entirely made of stainless steel, combined with an ergonomic design for easy disassembly and cleaning, makes the ReeFlow 200 series machines an ideal solution for the fresh food industry.

ReeFlow 200 machines are available in versions for wider products (200 TW, 200 BW), as well as in versions with the film roll positioned at the top (200 T) or at the bottom (200 B), depending on the nature and sensitivity of the product to be packaged.

They are equipped with a large, high-visibility touchscreen for easy parameter settings and the ability to store up to 100 different customized recipes.

By combining a ReeFlow 200 machine with the appropriate mechanical equipment (vacuum chamber, shrink chamber, drying chamber), it is possible to achieve Flow Bag packaging, which offers multiple advantages both in the quality of the final product and in reducing a company’s operating costs.

General Features:

• Robust construction

• Product contact surfaces made of AISI 304 stainless steel, compliant with international standards

• Infeed conveyor with pushers, length 1500 mm

• Cross-sealing jaw with LONG DWELL motion system, length 350 mm, high sealing pressure, suitable for hermetic sealing and MAP packaging

• Three pairs of longitudinal sealing rollers controlled by servo motors

• Fixed or adjustable forming system set, enabling film tube formation with longitudinal and transverse sealing

• Photocell for printed film

• No Product – No Bag function

• Maximum film roll width: 800 mm

• Outfeed conveyor: 900 mm

• Ergonomic design for easy disassembly and cleaning

• 100 programmable recipe memory slots

• Schneider PLC control system with 10” color touchscreen

Optional (Upon Request):

• Extension of infeed conveyor length

• Dual film roll holding system with automatic roll change

• Photocell for detecting product position inside the film before the sealing jaw, to prevent packaging errors

• Printer integration

• Reduced longitudinal seal for optimal aesthetic appearance of the final product

• Square-profile forming system

• Motorized air de-compression brush for removing air from the package

• Integration of an inline residual gas analysis unit for MAP packaging

• ReeNEXT platform for remote control and continuous real-time monitoring of machine productivity and consumption

The same machine can package products in a pouch with one side open (for final vacuum sealing) or with both sides sealed for MAP packaging.

Advanced Packaging Types:

By combining a ReeFlow 200 series machine with the appropriate equipment, advanced packaging solutions can be achieved, such as:

These packaging solutions offer several advantages: